Vietnam Paper Mill

Waste-to-Energy Project

Waste-to-Energy Project

TFB technology converts the mill’s waste (residue, sludge, biogas) into steam for internal use.

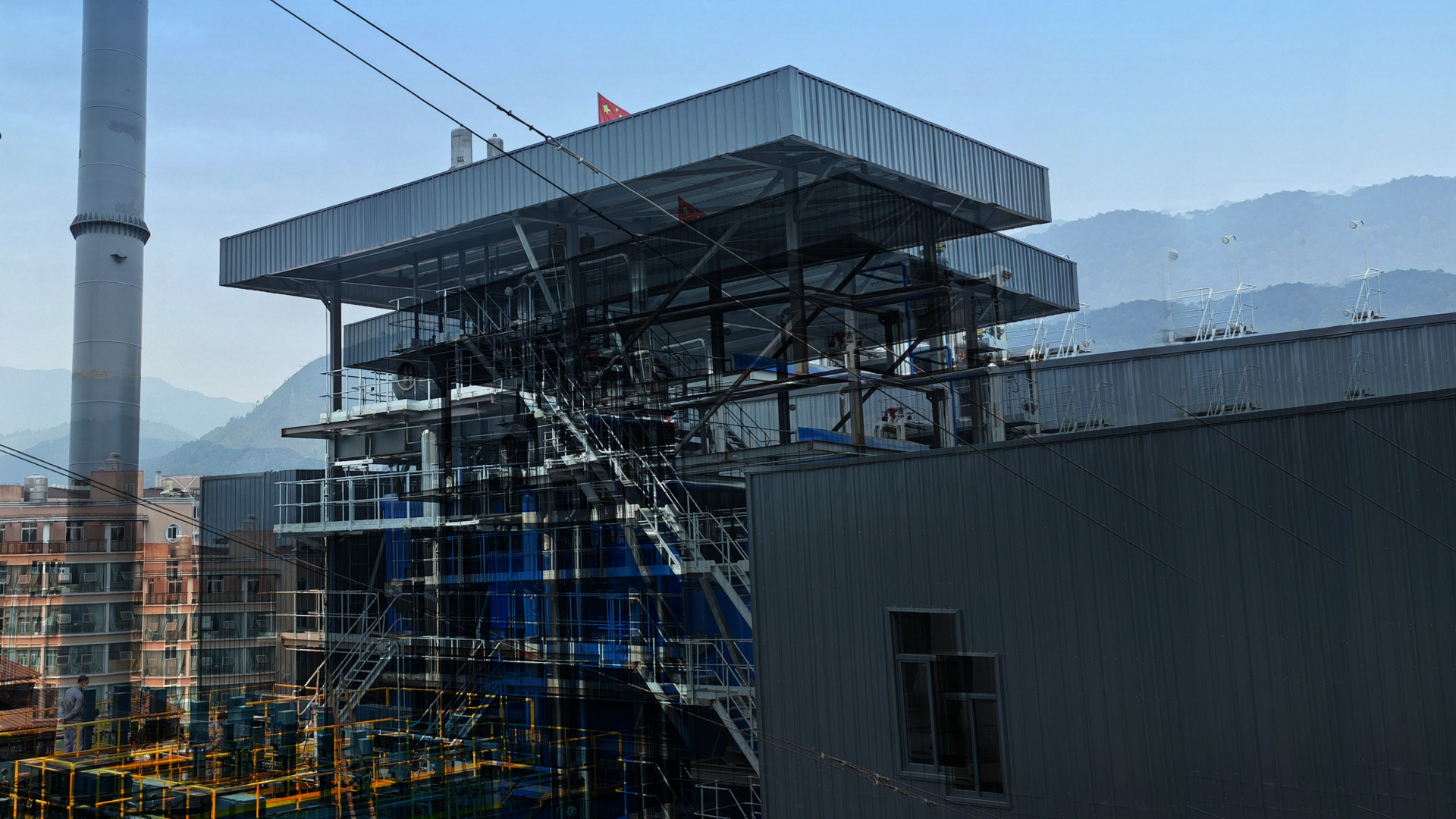

Challenge:

Meet incineration standards (>1100°C, >2s) while preventing slagging and NOx.