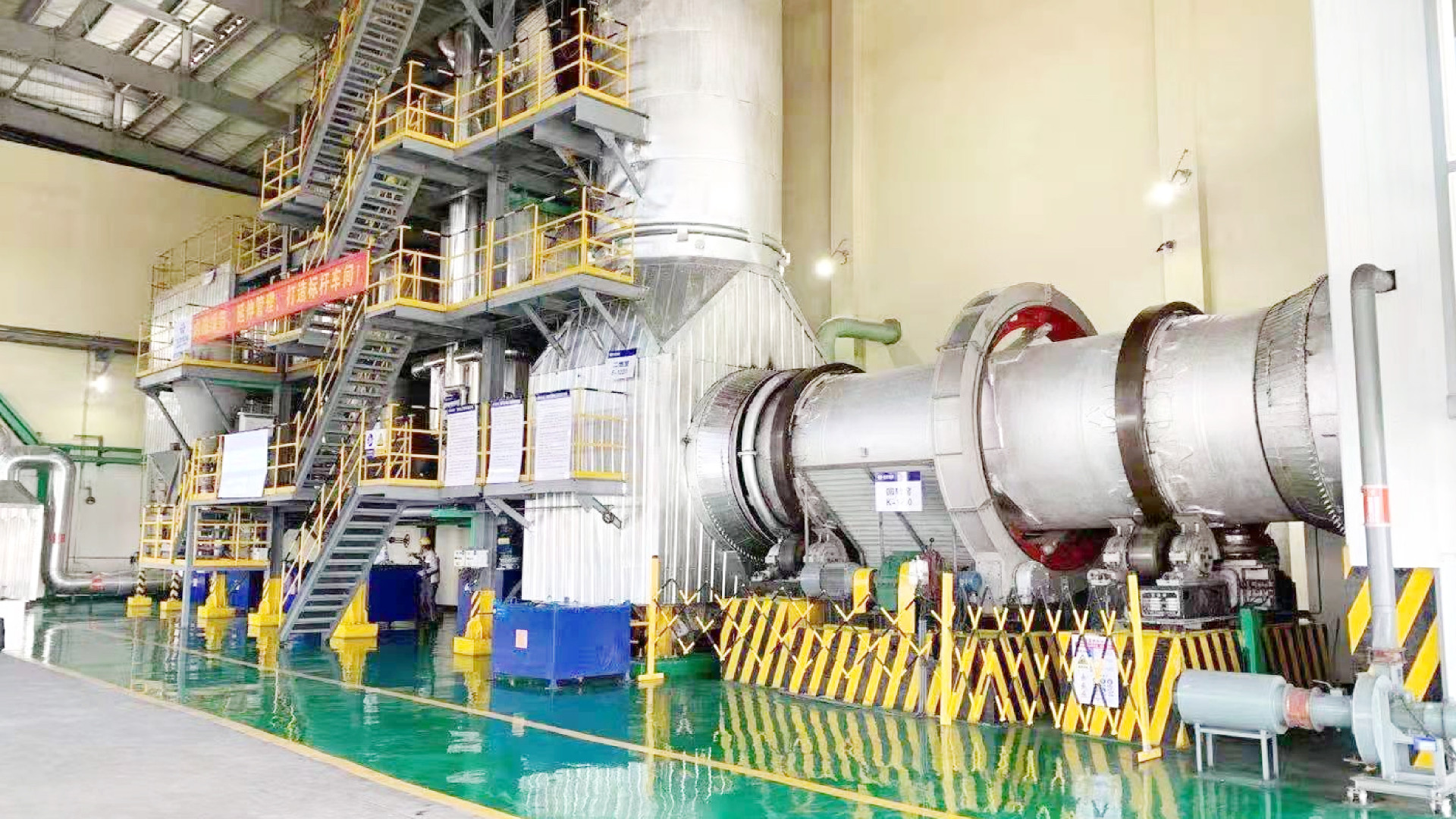

30,000 t/y

Hazardous Waste Project

Hazardous Waste Project

TFB safely treats diverse chemical waste and produces steam for power generation.

Challenge:

The hazardous waste stream is highly diverse and uncertain in composition.